What is the problem?

Many companies and brands started their journey with a small idea in a garage. Microsoft, Apple, Nike, and Harley Davidson took their first steps in their founders' home workshops, and now the whole world knows about them. Ukrainian enthusiasts are no less ambitious and rich in ideas. They wish to create, innovate, and change the world. But the war came to our land, and now the "garage revolutionaries" have their own front.

What is the solution?

Victory is forged not only on the front lines, but also in the rear. Those who until recently were engaged in purely peaceful affairs changed their work's focus and took up the improvement and production of things necessary for our defenders. Talented Ukrainians are zealously joining a do-it-yourself arms race to design and produce straps for machine guns, periscopes, power banks, mufflers, buggies, thermal insoles, helmets for the military, and so much more, for the common goal of bringing Ukraine closer to victory.

How does it work?

Power banks from electronic cigarettes

Mykhailo Voroshylo, an electric vehicle repairman from Chernihiv, makes chargers for the military from used electronic cigarettes. Power banks of large capacity are in high demand on the front line, and, according to Mykhailo, his DIY power banks can keep phones charged for three to four days, which can be vital on long missions.

It takes 28 batteries from electronic cigarettes to make one power bank. Mykhailo's friends and acquaintances help collect them. First, the batteries are recharged and sorted, then connected together and fixed into a case made using a 3D printer.

These power banks can work continuously for about 20 hours, but they have one drawback: it takes a long time to charge. The energy of the power bank is enough for up to 10 phone charges, depending on the phone's battery capacity.

Mykhailo says that if his power bank helps a soldier call their relatives at least once or send some necessary information to comrades, this device has justified itself 200%.

Mykhailo is working on improving his power banks and developing additional chargers for walkie-talkies.

Silencers for assault rifles and machine guns

Vitalii Panko, a police officer in the Sambir district of Lviv, produces silencers for Kalashnikov assault rifles in a small home workshop. These devices muffle the sound and flash from the shot, making them essential for reconnaissance groups operating with stealth and precision.

Panko started making silencers in 2014 when russia began its aggression in the east of Ukraine, sending his devices to soldiers on the front fighting heavy battles in the Donetsk and Luhansk regions .With the invasion in 2022, Panko updated and corrected the design and improved his device. Panko says he provides his products to soldiers at the front free of charge, "Because victory is our common goal."

Keeping soldiers warm

Ihor Diliev, a resident of the Kirovohrad region, makes chemical heaters for soldiers posted in the trenches throughout the cold winter using copper sulfate, salt, and sawdust shavings. The cost of one heating pad is less than 50 cents. In three months, Ihor Diliev has produced 3,500 of them.

Diliev only needs to purchase copper sulfate, while local producers provide sawdust, shavings, and salt with the craftsman free of charge. The single-use heating pad works by pouring the mixture of chemicals into a bag, and adding 20 milliliters of water. Leaving a hole for steam to escape, the heating pad can maintain a temperature of 60 degrees for 30 minutes, says Diliev, and can be used to warm hands and feet and put in the pocket of a coat or sleeping bag. Fighters have already tested the heater in the field, and it proved efficient, so now Diliev continues to receive orders for it from the front line.

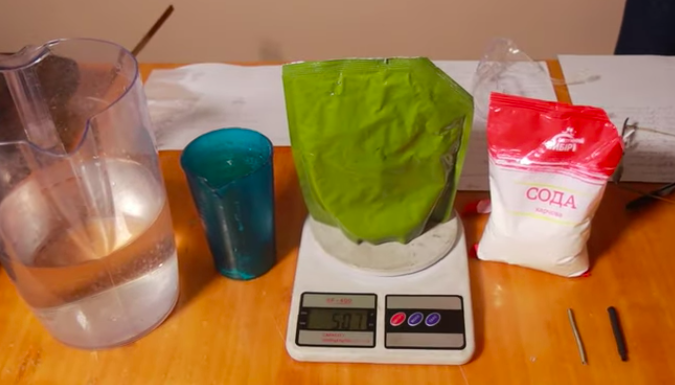

In Kryvyi Rih, craft teacher Oleksandr Viktorovych found another solution for keeping soldiers in the trenches warm. He makes heaters from ingredients that can be bought at any regular grocery store, and has been providing them to soldiers stationed in Zaporizhzhia, in the south of Ukraine.

Using his knowledge of chemistry, Viktorovych experimented with the proportion of ingredients until he came up with an effective recipe: a crystalline mixture prepared from acetic acid, water, and baking soda. Poured into a plastic bag, the warming device is activated by an ordinary metal spring. and can be used up to a thousand times, as long as the packaging remains secure. Aluminum or stainless steel flasks are the ideal packaging option for a heating pad. It is enough to shake them vigorously to start a heat release reaction. To "recharge" the heater, it can be placed in a vessel with water with the bag not touching vessel's metal walls, and boiled for 15-20 minutes.

Olha Minenko, a craftswoman from Lviv, has been volunteering since the beginning of russian aggression in 2014. She learned that doctors advise soldiers in the Azov Regiment to wear dog hair belts because they have a warming effect and can be used to treat various disorders, for relieving pain, and for rehabilitation, so she started making medical belts and socks for the Ukrainian military. She has since sent more than 100 such products to the front.

According to the craftswoman, it's too hot to wear dog hair socks regularly, even in winter, so she advises using such products only for therapeutic purposes. It is enough to wear them at night, or for a few hours during rest. Dog owners help the woman collect materials — sending packages with their pets' fur, even from occupied Berdyansk.

Before the war, Oleh Zemnukhov from Zhytomyr specialized in making products and accessories from hemp fibers, including clothes, shoes, accessories, cheese, and even sweets like hemp halvah from edible hemp. Now Zemnukhov produces heat-saving insoles for the Armed Forces of Ukraine using only eco-friendly materials..

The insoles, which can be used both in sneakers and army boots, are made from layers of burlap, hemp fabric, and canvas.

Zemnukhov explains that it is very important which insole contacts the skin of the feet. Synthetic or foam materials make the wearer sweat, thus making them wet and causing inflammation. Natural hemp insoles help to balance temperature.. "If you wear shoes with such insoles for a long time, your feet don't burn, the soles don't overheat, and your feet don't get so tired," Zemnukhov told Rubryka, noting that hemp fibers have additional antiseptic, bactericidal, and healing properties.

Periscopes, mine detectors, and water filters

Artur Magomedov, a teacher at the Reshetyliv Agrarian Lyceumhas been making periscopes for the military together with his students since March 2022. The group devised the idea of using 3D printers to make periscopes to help the military, figuring that if soldiers had a device look up from a trench or out from behind a wall without sticking their heads out, it could save many lives. About 2,000 of their periscopes have already been sent to the front line, Magomedov says.

Ukrainians who communicate with their friends and loved ones on the front line know all too well that access to clean water is a common problem.

A locksmith from Kremenchuk, Denys Silynnyk, makes periscopes and portable water filters at home for the Ukrainian armed forces,making it possible to purify water from heavy metals and bacteria.

The filter has a capacity of more than 3,000 liters, and can filter about two liters per hour without pressure and 10 liters per hour with pressure. The filter can be attached to large containers or to an ordinary drinking water bottle, and costs about $30 to produce.

Silynnyk says his team has already sent over 7,000 periscopes and almost a hundred filters to the front line, collecting requests using a Telegram bot.

Mykolaiv resident and volunteer Maksym makes mine detectors for the Armed Forces. Maksym started making metal detectors before the full-scale invasion, and in September, he began making devices for sappers, producing 10 pieces in two months, as well as repairing damaged mine detectors that can help save the lives of soldiers on the front lines.

The military, who use Maksym's devices, are satisfied with them. A sapper with the call sign "Bobryk" and his unit work in the Kherson direction and say that thanks to mine detectors from Maxym, they were able to neutralize ammunition of various calibers and explosive "souvenirs" of multiple purposes.

From cookies to drones

Before the full-scale war, Serhii Shpak from Kropyvnytskyi made products for confectioners and masters working with polymer clay. Now, instead of molds for cakes and cookies, he uses 3D printing to make drones and ammunition components in his home workshop.

During ten months of work, Serhii works around the clock printing plastic parts for damaged drones, as much as his 16 machines can work around rolling power outages, Serhii Shpak would like to increase production volumes. For this, he needs additional equipment, so he is looking for investors.

Light in the trenches

Ruslan Melnyk from Vinnytsia uses a 3D printer to make trench flashlights on the balcony of his apartment. Before the full-scale war, Melnyk worked as a parody artist. After the beginning of russia's aggression, he remembered that he had a 3D printer, which he had bought at the beginning of the COVID-19 pandemic. Then the craftsman bought 3D plastic, lithium-ion batteries, charging modules, and diode light bulbs to start making devices he calls "Fireflies." According to Ruslan, such a flashlight is charged via USB and can provide light continuously for about seven hours. Each of his lanterns has a magnet that can be attached to metal surfaces.

Ruslan says the first time he made such a flashlight for himself while fishing, and now they are essential in the trenches. Two of these are enough to light up the entire trench.

Since the beginning of russia's full-scale invasion, Melnyk says he has produced and delivered over 2,000 of products to Ukrainian soldiers. In a week, he makes an average of 15 flashlights and plans to buy a more powerful printer instead of the old and slow one to make three times more "Fireflies" for the soldiers.

Unlike the craftsmen mentioned above, Serhii Petrushevskyi, a volunteer from Zhytomyr, found a way of helping Ukraine's defenders without a 3D printer. He makes LED flashlights in wooden cases for the military. Carpenters from all over the country provide Petrushevskyi with wood. The size of the flashlight depends on the size of the battery box.

Since both men and women serve at the front, lighter and thinner flashlights are available to order. Although the batteries are smaller, they shine the same. Over three months of work, Petrushevskyi has produced more than 150 LED flashlights for the armed forces.

Forging victory in the rear

Carpathian blacksmith Ivan Bodnar helps to defend Ukraine. Before the full-scale war, Ivan worked in decorative metal processing for 14 years. He has been helping the Ukrainian army for many months now. At first, he made and delivered parts for bulletproof vests to soldiers, and then he began to make gas cylinders. He also forges bells from artillery shells.

Ivan Bodnar shares that the forge has been helping the Ukrainian resistance for a long time — even his grandfather, also a blacksmith, used it as a hiding place for Ukrainian Insurgent Army, a nationalist paramilitary and later partisan formed during World War II.

Bodnar is sure that every conscious person should understand the importance of helping the soldiers whenever possible.

"If we don't support our army, we will feed someone else's," the craftsman concludes.

Volodymyr Dubrovskyi is also a blacksmith — until February 24, 2022, he made metal products to order. In the first days of the full-scale invasion, he joined the Territorial Defense ranks and now serves in the Armed Forces of Ukraine. Although he has much less free time, he spends it in the workshop, making stoves and pans for the front from leftover materials.

"We want to make the boys happy so that they know they are cared for, thought of, and not forgotten," Dubrovskyi says, adding that the military likes to cook on the craftsman's pans he makes from agricultural machinery elements.

Odesa welder Ihor Romanov makes mobile kitchens suitable for field conditions in his garage workshop. One kitchen weighs 15 kilograms, fits in the trunk of a car, and can be installed in a trench or dugout.

"There was an issue of where to cook food," the welder says. The first three kitchens were sent to the military in Mykolaiv; they checked them and expressed their wishes." Based on their requests, Romanov improved the design to consist of three parts — a base, a grill, and a module for a cauldron.

The handyman works on these mobile kitchens alone, spendsing a whole day to make one. Since May, he has already made 42 such devices.

Vyacheslav Polakh from Kharkiv manufactures metal staples for the front. Fighters use staples made of steel rods to strengthen positions. In nine months, Vyacheslav has produced and delivered more than 30,000 staples to the front.

Before the war, he made metal tables, chairs, and racks for restaurants and offices. Now he directs his efforts toward supporting the front.

Vyacheslav says he is proud to have as regular customers border guards working to fortify the border between russia and the Kharkiv region, where he lives with his two year old daughter. "I work understanding that my family's safety depends on it," Vyacheslav explains."We did not leave Kharkiv, and this is my direct motivation."

Belts and pouches for first-aid kits

Artem Salyvin from Okhtyrka has owned a workshop for restoring shoes in Okhtyrka for the past 10 years. Together with his friend and volunteer Pavlo Ihnatchenko, he sews pouches for military first-aid kits.

Salyvin says that he can sew about 10 pouches per day, and that they regularly consult with the military and doctors on ways to improve their products.

One of the Ivano-Frankivsk workshops produces handmade belts for the Ukrainian military. In addition to the usual belts, craftsmen also create belts for weapons and tools used in the trenches.

Tetyana Shchebelska, head of a small manufactory, explains that belts for the military differ from those used in everyday life because soldiers may need to hang weaponry, ammunition, first-aid kits, and many other things on them – so they must be extra strong.

These belts produced in Shchebelska's workshop are extra wide, and may have two or three points. They also produce special gun straps that can be adjusted to any machine gun. The craftswoman makes all the belts herself, and an Ivano-Frankivsk jeweler makes the fittings. In total, she says that about 300 of her products have been sent to the soldiers at the front.

Buggies to the front

Volodymyr Sadyk, an entrepreneur from the Chernivtsi region, creates "VOLS" buggies with his team and sends them to the front line. Before the full-scale invasion, Sadyk worked as a locksmith for more than 20 years. Since February 2022, he says he has made and delivered 50 military vehicles to the front.

"VOLS" buggies are used for both offense and defense by snipers, medics, and partisans. A 38-liter gas tank and a small internal combustion engine provide more than 500 kilometers of travel without the need for refueling. The vehicle is easy to maintain, accommodates machine guns and grenade launchers, and has a separate section for evacuating wounded fighters from the firing lines.

Each car costs about $5,000 to make. Sadyk says he has collected donations from the residents to produce the vehicles, and recalls even a little boy from the small town of Storozhynets participated and gave him about $350, which he had earned selling homemade donuts at the market.

Camouflage from an artist

Serhii Novosyolov disguising a trailer with a bath complex used by the military

An artist from Poltava, Serhii Novosyolov, used to create graffiti before the start of the full-scale war, and now he camouflages vehicles for the military, painting almost three dozen vehicles so far.

The military orders the color and types of camouflage from the artist. About 18 cans of paint are needed to disguise a bathhouse on wheels. Charity donors help the artist with supplies, and Serhii makes cardboard stencils himself. The artist also uses natural materials in his work.

"Dry weed is also a pixel. By applying paint through it, the car becomes rippled, which makes it a good defense," Serhii Novosyolov says.

Helmets for the Armed Forces of Ukraine

Three Khmelnytskyi residents improve military helmets in their own workshop. Andrii, the conceptual developer and founder of the workshop, says they have been working this way since 2016. During this time, 3,000 helmets were improved, almost a third of them in the past year alone. Depending on the military's needs, craftsmen can install radio headsets, night vision devices, or camouflage for the helmets. They are also working to modernize the latest Ukrainian TOR-D helmet by adding their patented suspension system, cushion, and covers.

"We have already put into production an analog of the American FAST Ballistic High Cut helmet, which is most often used by military personnel of the special forces, as well as mortar and artillerymen. These helmets are "earless". In addition, we have a combined military option," the creators say.

Khmelnytskyi craftsmen work say they work tirelessly to ensure orders for military personnel performing combat missions as are filled as quickly as possible. According to the creators, even the commander-in-chief of the Armed Forces of Ukraine, Valerii Zaluzhnyi, has two helmets they modernized.