Pivdenmash today: how Ukraine's largest rocket and space enterprise lives

One official working day, salary delays, and world-renowned development. What does the everyday life of an industrial giant look like?

The father of military and peaceful missiles. 744-hectare giant, located in Dnipro center. A city within a city and a place of secrets. Pivdennyi Machine-Building Plant named after Oleksandr Makarov is Ukraine's space business card. It is its products that have allowed our country to compete in the universe's study.

In Soviet times, every third city resident worked here in a factory or had relatives who did. 62,000 people used to work in the shops, and now there are hardly 5. Instead of the standard week, there's now only one official working day, Monday. The reports include salary delays, layoffs, and demonstrations.

What was the reason that such a giant was out of the game? How does the country's largest rocket and space company live today? Does it really live or maybe decay? Our journalist visited Pivdenmash.

NOTE

The automobile plant in Dnipro was founded in 1944. Its first products were simple machines, amphibious vehicles, and truck cranes. Because of the arms race with the United States, the Soviet Union began to look for places to produce defense missiles. The choice turned next to the newly created company. In 1951, it was renamed the Dnipropetrovsk Machine-Building Plant №586. The Design Bureau "Pivdenne" is being created on the territory. "Kosmos", "Kosmos-2", "Tsyklon-2", "Tsyklon-3", "Zenit-2", "Zenit-3SL", "Dnipro" are launch vehicles made in Dnipropetrovsk.

Currently, they are engaged in foreign products here: the first stage of the Antares and the Vega engine, assembling Belarusian-made trolleybuses for Ukraine, and producing trams. The plant doesn't receive large orders (defense or space ones) from the state.

"Pivdenmash" comes to life in the morning

With the first sun rays, people are already scurrying near the plant gates. They run and limp, hurry to their work shift. It takes them a few minutes to enter: all you have to do is show your ID to a conscript.

Outsiders cannot get inside. This requires special permits. We had to issue them to create this article. Be sure to read the safety information at the entrance. Our guide Svitlana briefly explains its content: photographing only what's allowed, and not feeding squirrels.

A large area stretches behind the gate: a spacious area planted with trees and shrubs. On the left, Oleksandr Makarov (chief engineer and head of the plant; with him the company flourished) is watching everything that is happening, on the right, we see a "Perymetr" missile or as it's called, "Hand from the Coffin". Dozens of buildings are crowded around the square, we can see the domes of the church in the distance, and it's clean everywhere: you can't see any wrappers or cigarette buds around.

"Face" of Pivdenmash

We are led for 10 minutes along several buildings. We joke that if you walk like this every day, you'll definitely not get overweight.

"We'll work, and time will show"

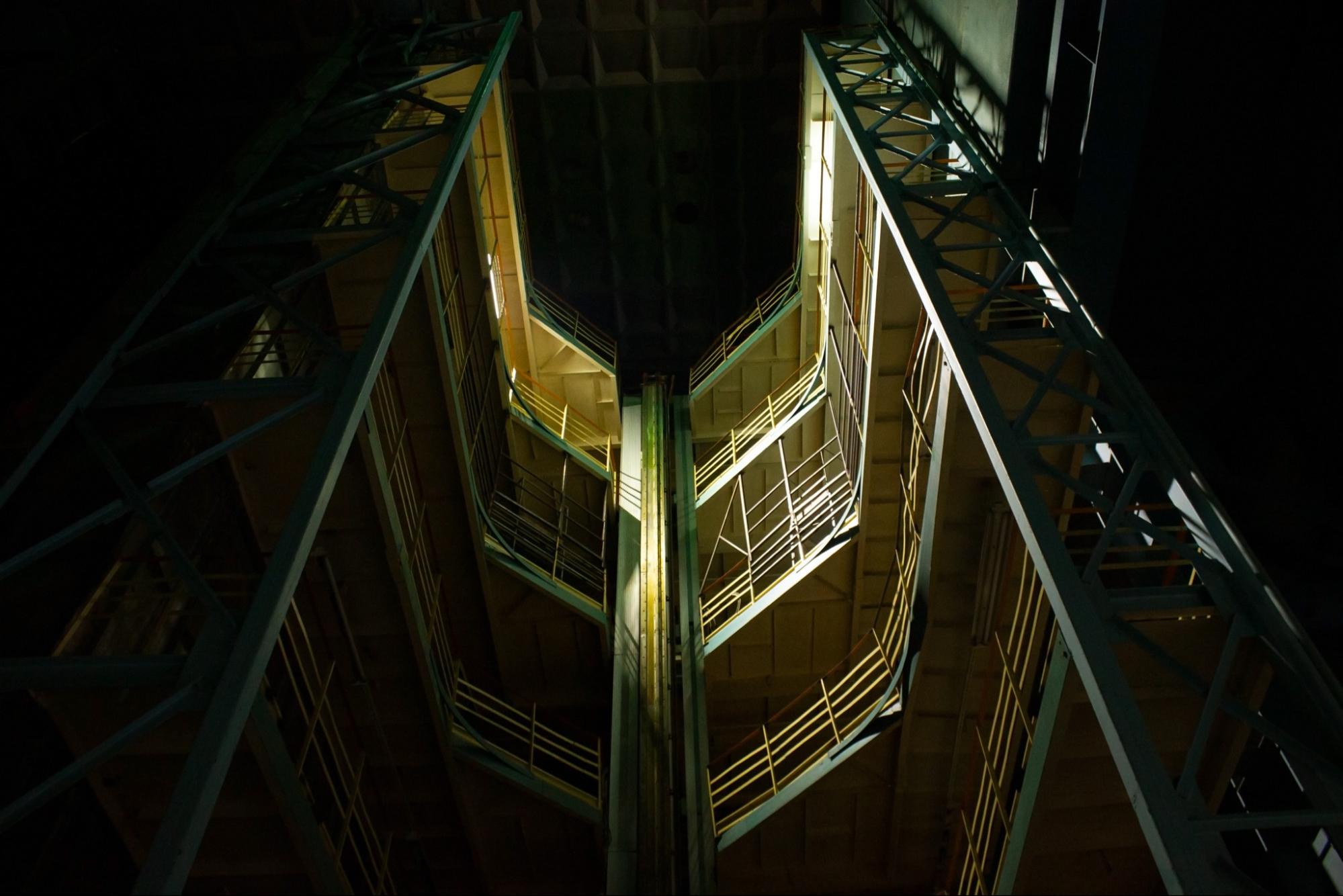

97th shop. Assembly place. Under the 30-meter ceiling, there are huge tanks. These are the skeletons of future rockets, where their burning blood, fuel, will store. Nearby, we can see various details which hardly remind other parts of carriers. Here they stand in the cool: under the April sun inside, it's +10 degrees.

Mykola Vatamaniuk, the deputy head of the testing department, tells us that the photographer and I are underclad, and have to look very closely at our feet because the floor is dotted with tracks on which rocket parts are transported. He has been working at Pivdenmash for 36 years. He graduated from the National University of Shipbuilding in Mykolaiv, got to Dnipro by distribution. "We'll work, and time will show," he thought then. And the time has been showing for 4 decades.

"In those years, the quantities were large, the orders were different, and there were more people. We used to work in two shifts, now just one. Only additionally, we bring people to separate processes. The most interesting thing about us is the employees and the team in general. We're all united."

Mykola says that we are lucky today. There are a lot of spectacular things in the shop. Therefore, the photos will be good. The first process is washing the details of the launch vehicle.

What is currently produced at the plant?

The 17-meter tank lifts a huge crane like a feather. The fuel container is sent for de-greasing. First, it will be washed by hand, and then by secret technology, jet grouting (we talked about it in the article about the aerospace center). In the end, the tank will be ready to work.

"Spotlessness is a guarantee of launching into space," says Mykola Vatamaniuk.

This tank will go to the United States, where it will be part of the Antares rocket carrier. It's one of those currently produced at Pivdenmash.

"Current production in this area is 2 rockets a year. We're working on them with the Pivdenne design bureau and several related Ukrainian companies. We create the design, send it to America. It's assembled there, and they carry out a mission to deliver cargo to the ISS," says Oleksandr Baranov, director of the plant for manufacturing and testing of liquid rocket engines.

ANTARES LAUNCH

The second rocket carrier in the production of which Pivdenmash participates is Vega. It is handled by the European Space Agency. Here at the factory, they make a 4-speed engine.

"We've made six engines last year. And now the stock of EC launches is three years. We're waiting for a new contract for 10 more engines. Our production is now preparing for this task (While working on this article, they received a contract for 10 engines)."

VEGA LAUNCH

"Work is still underway to test several types of liquid engines. It's the development of the Pivdenne Design Bureau. Everything on environmentally friendly fuels. They also started ground testing of the engine of their own development, the gas generator is being prepared for the first tests. And we also hope for implementing a joint project with Canada, 'Tsyklon-4m.'"

They're not only engaged in space orders here. They assemble trolleybuses and trams here for the city and Ukraine. Trolleybuses drive around Dnipro, but the latter go abroad, for example, to Turkey, or the capital. One of these is currently being tested on the city streets.

"We lack support"

The best times for Pivdenmash were the Soviet and the first years of state independence. And 2014 was a turning point.

Ukraine has severed ties with Russia. Because of this, the "Morskyi Start" program was suspended. According to Pivdenmash employees, the launch of Zenit brought about 80% of revenue. They also lost contracts with other countries, the United States and Brazil. From there, wage delays and cuts began.

If it weren't for these events, the plant could've been successful, Oleksandr Baranov says. There would be more projects and more opportunities. The pandemic struck the last blow.

"We were supposed to start joint projects with India, Saudi Arabia, and other countries, but the coronavirus has set its priorities. At this time, many states have other things to worry about besides space. That's why some projects have been paused, others have been postponed."

Currently, the plant hasn't paid the full salary for October 2020. Last fall, the state allocated 210 million to repay the debt. And they quickly ran out. Oleksandr Baranov says that the state supports the company, but it's still not enough for such a giant.

"We lack state support in terms of assistance on such global issues as preferential taxation, preferential energy tariffs. There's a lack of promotion of such professions as an engineer, design engineer, technician engineer."

There's also a lack of a space program, a plan for industry development for the coming years. The last one ended in 2017. In January, the government approved its concept for 2021-2025, so now the document is sent for approval to the relevant departments and ministries.

Intergenerational welding

Mykola Vatamanшuk points to a huge welding machine. It's located on a tank that rotates on its own, and the seam connects its parts. Workers on its sides: Mykola Yefimovych on the left, and Maksym Fedorovych on the right. And the age difference is 62 years. Because the older man was born in 1937, and a guy, in 1999.

Mykola Vatamaniuk talks about the couple because there's no other opportunity to communicate with them in person: they'll do welding for 2 hours.

"Mykola Yefimovych came here when he was still a minor. And now he passes on his accumulated knowledge to a young man. He wasn't afraid to start working for us. A handsome young man is quick on the draw and has a clever pair of hands. But there are few of such men."

Indeed, there's a problem with the junior staff at the plant: they don't want to go to work in the shops. Turners, plumbers, electricians, or welders–like Maxim–are simply impossible to find, Oleksandr Baranov says.

"It's not prestigious, it's not expensive in terms of wages. And the prospect is very bleak. Pivdenmash cannot change this. To make the prospect brighter, the state must draw a road map. 'If you study to be a specialist, we'll give you a superb job. You'll be a very respected person in this country and the world in general.' Until the road map is drawn, young people will continue to go to Poland to pick apples."

Why order at Pivdenmash or Four Nines of Reliability

Several people crowd at the tables. Parts are on the table. My guide explains: these are the valves that will be on the Antares. They're currently being tested.

"Once-two-three, let's go!"

"The valve is repeatedly tested to get to the installation. Even at the dawn of concluding the first international agreements, foreign customers were sometimes shocked by the number of inspections at all work areas," says Oleksandr Baranov.

They've always required the products to have high reliability, 99.99%. One-tenth of a percent was left to fate.

"You won't find a greater degree of reliability anywhere. In other countries, it is 99.3, and we have always had four nines. And the price offered by Pivdenmash is competitive on the market. It has always been and remains, given our level of economic development."

Oleksandr Baranov calls a colossal experience the plant's advantage. The equipment produced here has always required high performance. They've never had a right to make a mistake. That's why they chose the appropriate slogan: "Quality, tested by space."

Despite the problems they face every day, the factory continues to work here. Employees are convinced that their work is important, so they don't stop it. Oleksandr Baranov sums up: he says that any night ends, so the dawn will come.

Photo: Oleksandra Tkach for Rubryka