Mushroom foam: how Kherson researchers discovered a new material

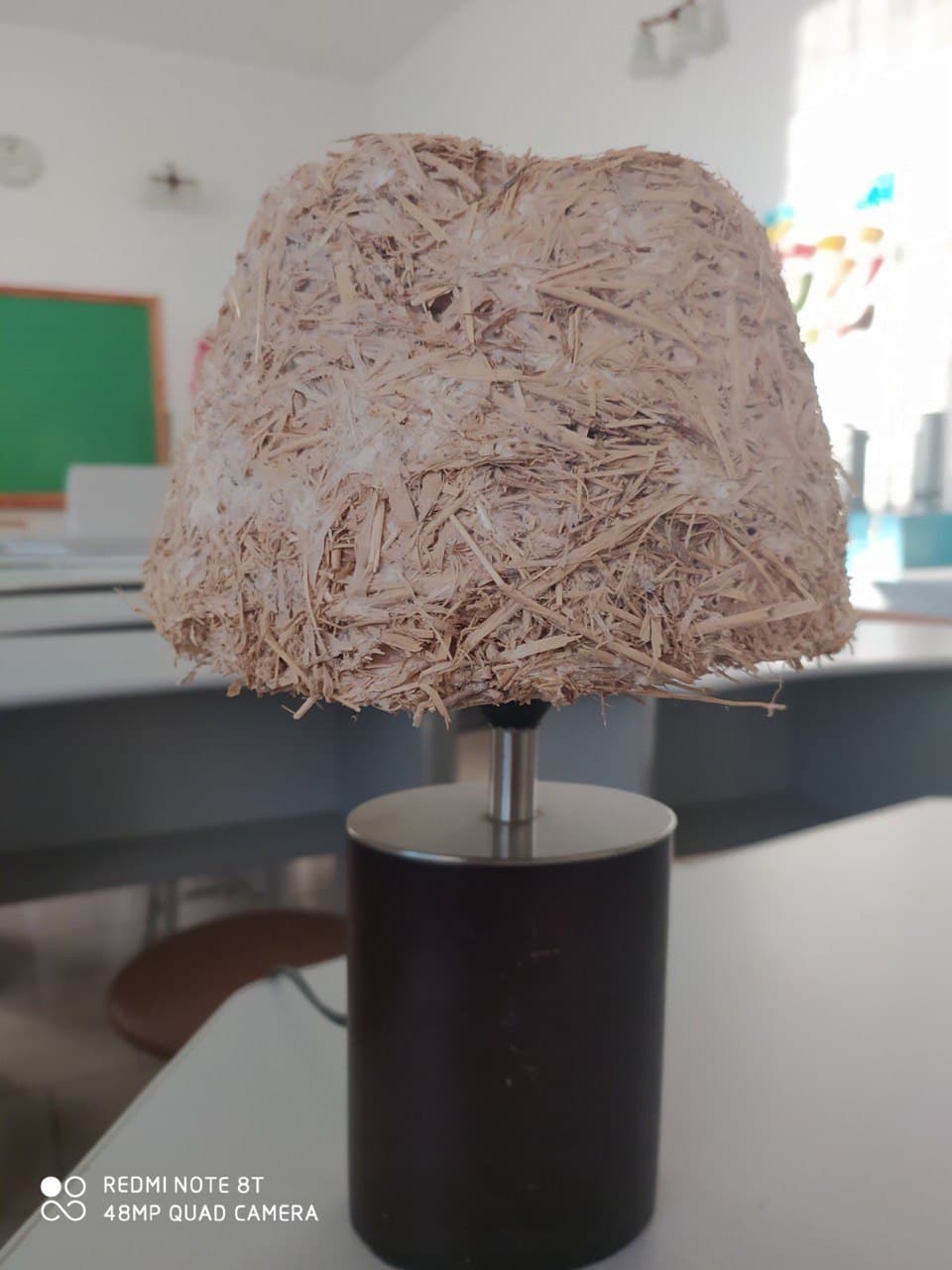

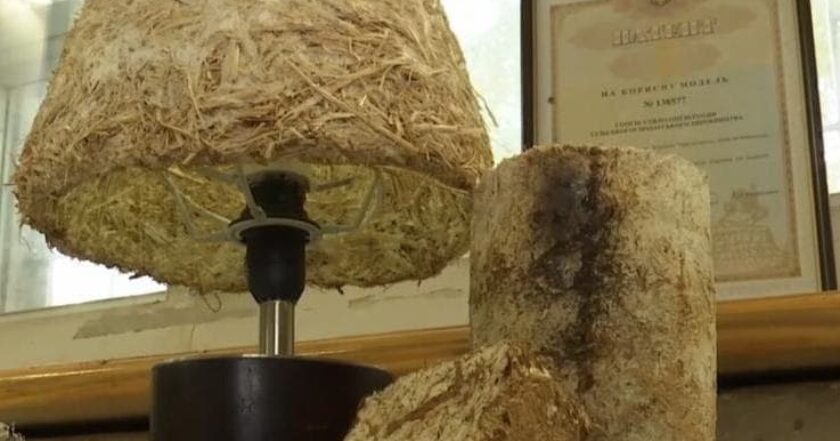

They've already used it to create lampshades, vases, mugs, and even paving slabs! Scientists say that this biomaterial is five to six times cheaper than synthetic plastic, and also doesn't emit toxic waste that can poison the soil, air, and water.

Caring for the environment has become a real global trend in recent years. Progressively more people in different parts of the planet understand that nature's resources aren't eternal. The Earth cannot digest billions of tons of plastic waste generated by humankind for an infinitely long time. An ocean filled with drifting junk, giant landfills on land, animals injured and killed by synthetic waste… Plastic has even been appearing in geological studies.

Bio-plastics can be a promising replacement for conventional plastics, as it solves two problems at once: reducing oil use and decreasing global pollution. Currently, the amount of plastic acquired from biological raw materials is about 1% of polymers available on the market, and it has a steady upward trend. In 2019, the bio-plastics market was estimated at $7 billion, and researchers predict that in the next five years it'll continue to grow by 16% every year.

In the 19th century, there were first attempts to use plants for producing plastic. In 1856 in Great Britain, they created Parkesine bio-plastic based on vegetable cellulose, which was to replace ivory. Later, in the 1930s, Henry Ford used soybean material to produce auto parts. Unfortunately, raw plant materials were replaced by a cheaper alternative — oil. Only in the 1990s, new technologies appeared, making eco-polymers' production commercially viable.

Now manufacturers use every imaginable raw material to produce bio-plastics: sugarcane, potatoes, corn, cassava roots, castor oil.

Kherson State Agrarian University accidentally invented a way to produce eco-material similar to plastic… from mushrooms. While experimenting with oyster mushroom growing technologies, Kherson agrarian scientists created a natural foam.

It all started with mushroom experiments

The Department of Processing Technologies and Storage of Agricultural Products of KSAU is focused on processing livestock and crop products, including mushroom growing ones. Here agronomists (Agronomy specialty) study the chemical composition and yield of mushrooms. Food technologists (Food technologies) work on types of heat treatment, taste, conduct experiments to develop recipes. For example, the latest is the production of mushroom powder for soup kits, pasta with mushrooms powder, dried oyster mushrooms in pieces for dressing julienne, etc.

"For the experimental analysis of the difference between freshly picked oyster mushrooms and ones kept in the store, I brought mushroom blocks to the department, and we grew oyster mushrooms," Ihor Chernyshov, associate professor of the department, says, "We left a processed block in the utility room. When it dried up, my colleague Maksym Levchenko noticed that the block's structure became similar to polyfoam in weight and properties, and suggested trying to make various products, which we can use in everyday life, from it."

In order for the products to be light, but simultaneously strong and functional, first, they started searching for the ideal substrate. It was important both to get the best version of plastic and use agricultural waste for this purpose. At this stage, another employee of the department, Hennadiy Karashchuk, joined the team.

The pioneer and "inspiration" for the experiments was a standard substrate for growing mushrooms made of sunflower husks and wheat straws. Subsequently, they attempted to work with almost all plant agricultural waste, i.e. grain straws, flax shives, corn cob spathes, soybean husks, peas, millet, rice, green grass, and hay. Researchers have already identified the best of them, but so far they are keeping them a secret.

Growing polymer in… a pot

Forming mushroom plastic usually takes 2 weeks. The technology is simple: they place the mixture infected with the mycelium in a special container; the mycelium is let to develop and secure the substrate; after that, they stop the mycelium development. Then the material fermented by the mycelium activity is dried. It takes several hours in artificial conditions, and five to seven days in natural ones. University students also take part in the scientists' work. The department has a "Technologist" scientific group, where students, interested in mushroom growing, conduct experiments to determine the growth rate of fungi, yields, study strains, and carry out tasting of new products. When creating bio-plastics, the boys, members of the group, were responsible for shredding straw and pasteurization.

According to the inventors, the term bio-plastic isn't quite correct. It's rather a complex polymer of cellulose, plant lignin, and fungal chitin. Many advantages of this material over plastic from carbohydrates are:

- it's made from agricultural waste (it eliminates incineration in the fields);

- it's absolutely waste-free production (even water after pasteurization becomes a valuable fertilizer);

- a mushroom polymer is an environmentally friendly natural product without adhesive components, emissions of decomposition products, etc.;

- easy and fast utilization of the processed product by composting (it decomposes in the soil in a month, improving soil structure, and serves as forage for worms and soil microorganisms);

- the product itself has a pleasant smell of mushrooms, a unique surface pattern and a texture that doesn't repeat, and a small mass.

However, there are disadvantages: the material is prone to rotting at elevated temperatures, flammable, and difficult to standardize by physicochemical properties.

Patented material invented by KSAU is like papier mâché, loose fiberboard, or foam in structure, from soft to dense. It's easy to cut and crumble, but it also doesn't require processing, since the shape is set when the containers are filled with substrate.

In a couple of months of experiments, the department created several familiar everyday life things, i.e. a lampshade for a lamp, a beer mug, a vase for flowers. They obtained samples of paving slabs, experimented on the production of facing tiles for interior decoration, and made molds for craft thermo-glasses. They plan to make Lego molds for producing Lego bricks for the construction and insulation of houses. Researchers would like to make more massive products, but the insufficient area of laboratories hinders them.

From flower pots to "living facade"

In fact, the issue with the premises for their department isn't new. "When I showed up to the profile committee requesting to allocate a building to me to rent, I usually heard deputies saying: why did you come here again?" Ihor Chernyshov shares his pain. "For six years, I've been squeezing out the permission for privatizing the written-off premises for the production of mushrooms at the regional council. The result is zero!" Grant funds or a future investor who'll set up mass production of consumer goods or building materials from a unique, environmentally friendly material might remedy the situation. Documents for a grant at the inventors' department are already being prepared. Scientists are sure that the material they obtained has every chance for the future.

Inventors of mushroom bio-plastics from Kherson, Hennadiy Karashchuk, Ihor Chernyshov, and Maksym Levchenko

"Our bio-plastic makes a good insulator, like foam in properties, also beautiful pots and lampshades for lamps, even garden furniture. The products can withstand any temperature in the negative or positive ranges, except the combustion temperature, of course. The most important advantage of this bio-material is five to six times cheaper price than synthetic plastic, and it also can last as long. Synthetics decompose in more than a hundred years, and our bio-plastic turns into one hundred percent compost in a month, like fallen leaves. More so, no waste occurs that can poison the soil, air, and water."

They've got many plans for the future. "Of course," Ihor adds, "Apart from continuing research in mushroom growing, we have a lot of other ideas. It's clear that we're constrained by the lack or imperfection of material and technical resources, and we try to maneuver between wanting and being capable. We have an idea to develop new coatings for building facades. The pilot name is living paint. The coating will be alive, will grow, absorb carbon dioxide, noise, and dust, and emit oxygen.

So we work!"

Watch how to insulate a house with hemp. The Ukrainian spoke on his method for EcoRybryka.